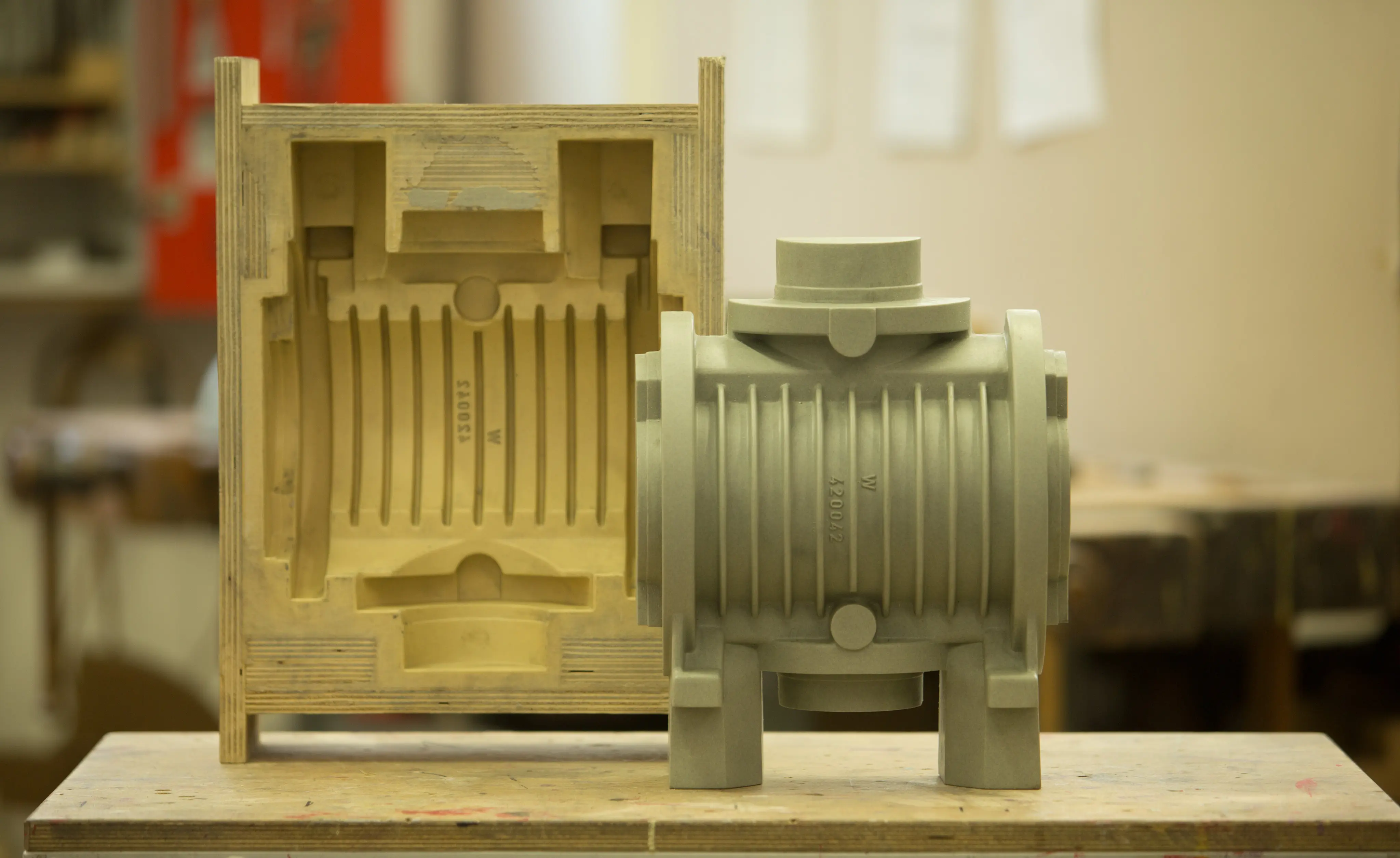

Traditional craftsmanship meets modern manufacturing technology

Before every casting comes the model – crafted from wood, polystyrene, plastic, or metal with the highest level of craftsmanship and precision. Our in-house carpentry enables accurate and rapid production of custom models directly on site. Existing models are repaired, modified, or restored as needed – for example, when machining allowances change or geometric adjustments are required according to customer specifications. On request, all modifications to existing models are carried out entirely in-house, based on 3D data or technical drawings, ensuring short response times and transparent processes.

From model to mould – consistent quality throughout the casting process

All models are managed with clearly documented drawing numbers and version statuses to ensure traceability and consistency in series production. Our high-bay storage system with over 20,000 stored models guarantees quick access and efficient workflows in manufacturing. After completion of model making, the models are handed over to our moulding and core-making departments. There, the moulds and cores are produced based on the verified models, forming the foundation for the subsequent casting process. Precision in model making ensures dimensional accuracy and repeatability throughout the entire casting process.