Efficient surface cleaning

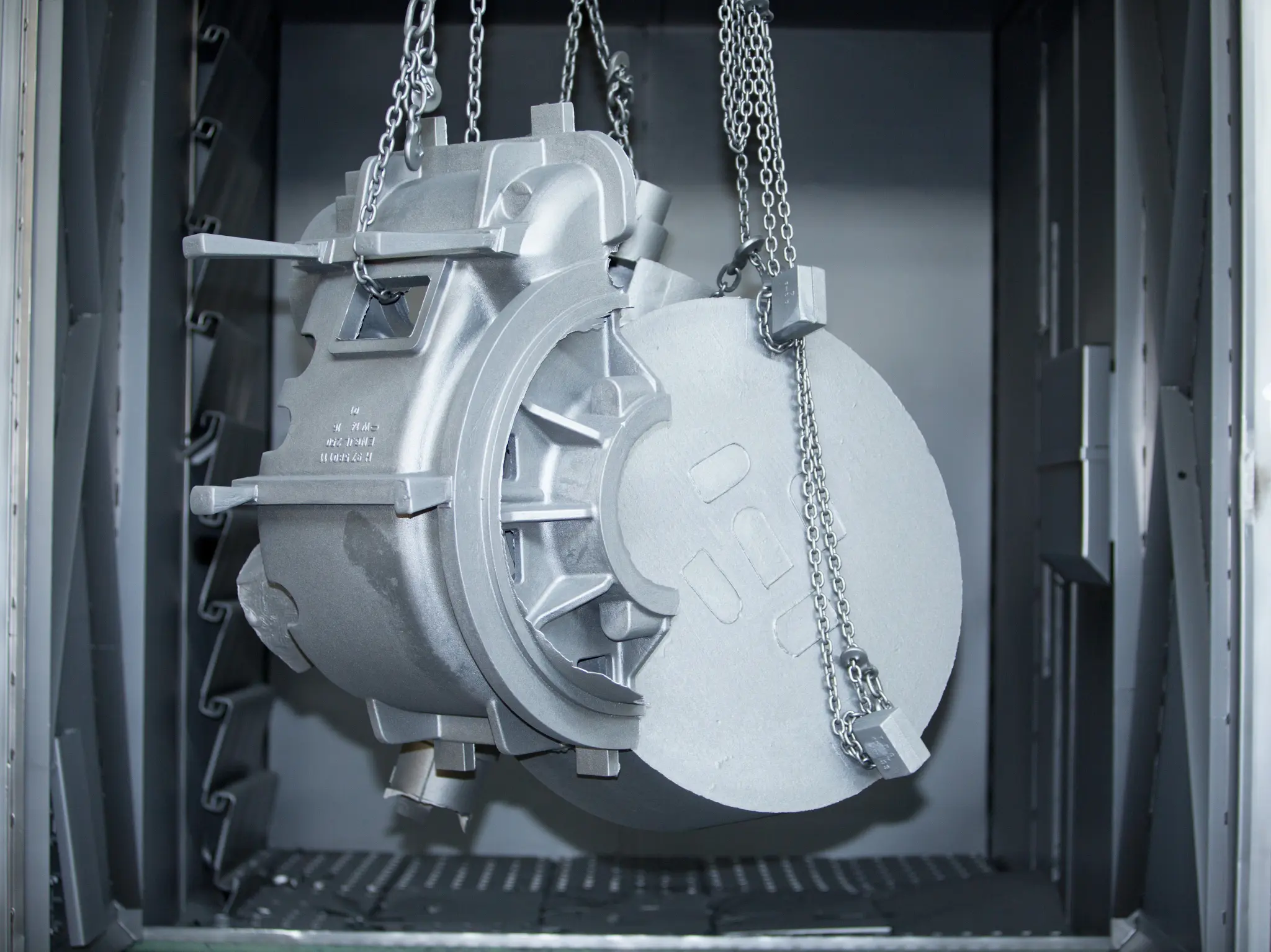

After shakeout, the castings are cleaned in our modern overhead rail and free-jet blasting systems. Sand residues and burrs are removed reliably, producing even surfaces and optimal preparation for subsequent operations. The systems can handle large castings up to 3000 × 3000 × 2000 mm, with standardized parameters ensuring consistent surface quality.

Integration in the production chain

Depending on requirements, the cleaned castings undergo further processes such as heat treatment to achieve desired material properties, or machining for final dimensional accuracy. This integrated workflow ensures consistent quality and efficient throughput across all production stages.

Additional Services for Perfect Castings – Everything from a Single Source

In addition to the casting process itself, we offer a comprehensive range of supplementary services to refine, machine, and prepare your components for their final application. From clean blasted surfaces and precise heat treatments to high-quality coatings, mechanical machining, and induction hardening – every step is carried out with state-of-the-art technology, many years of experience, and the highest quality standards. The result: dimensionally accurate, robust, and visually flawless components that precisely meet your requirements.