From raw casting to precision part

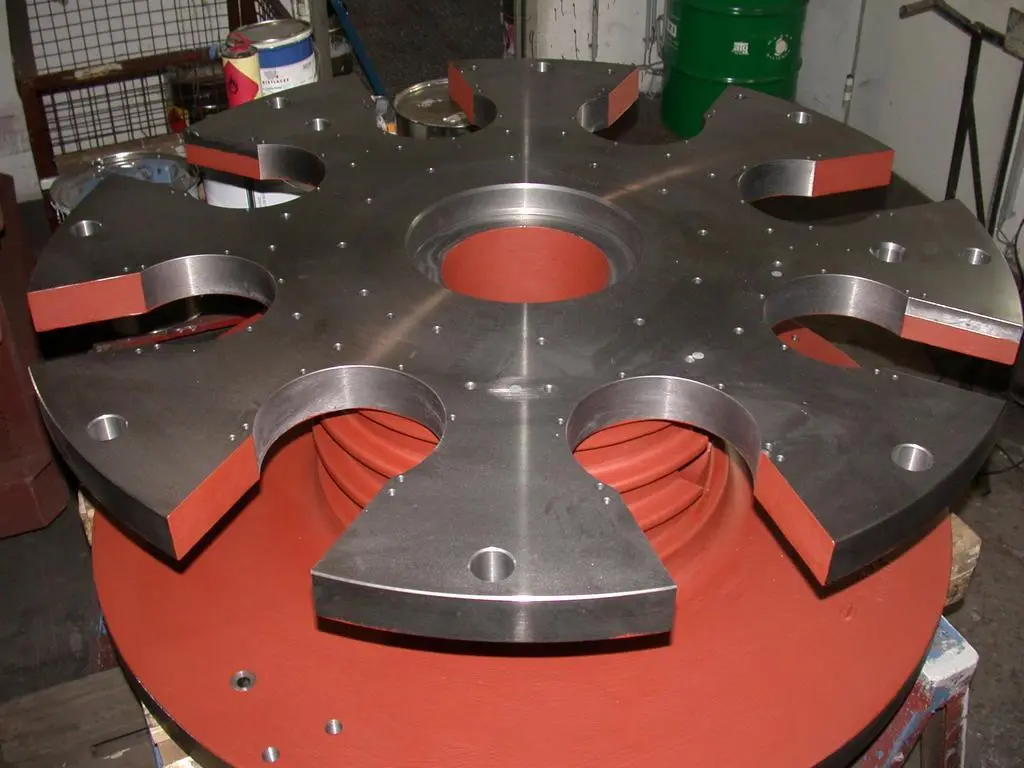

After blasting, the castings pass through our fettling process, where risers, feeders, and surface irregularities are removed. Non-destructive testing methods such as impact, visual, magnetic particle, or dye penetrant inspection ensure flawless material quality. Modern CNC-controlled milling, turning, and drilling centers then produce finished components with outstanding dimensional accuracy and surface quality.

Integrated manufacturing and documentation

Each machining step is measured and documented to maintain tight tolerances. Our experienced specialists ensure efficient and repeatable processes for grey and ductile iron parts. Machining includes roughing, finishing, milling, drilling, and fine machining – optionally with dimensional and inspection reports. By integrating machining in-house, we reduce transport routes and lead times, delivering fully assembled castings from a single source.

Additional Services for Perfect Castings – Everything from a Single Source

In addition to the casting process itself, we offer a comprehensive range of supplementary services to refine, machine, and prepare your components for their final application. From clean blasted surfaces and precise heat treatments to high-quality coatings, mechanical machining, and induction hardening – every step is carried out with state-of-the-art technology, many years of experience, and the highest quality standards. The result: dimensionally accurate, robust, and visually flawless components that precisely meet your requirements.