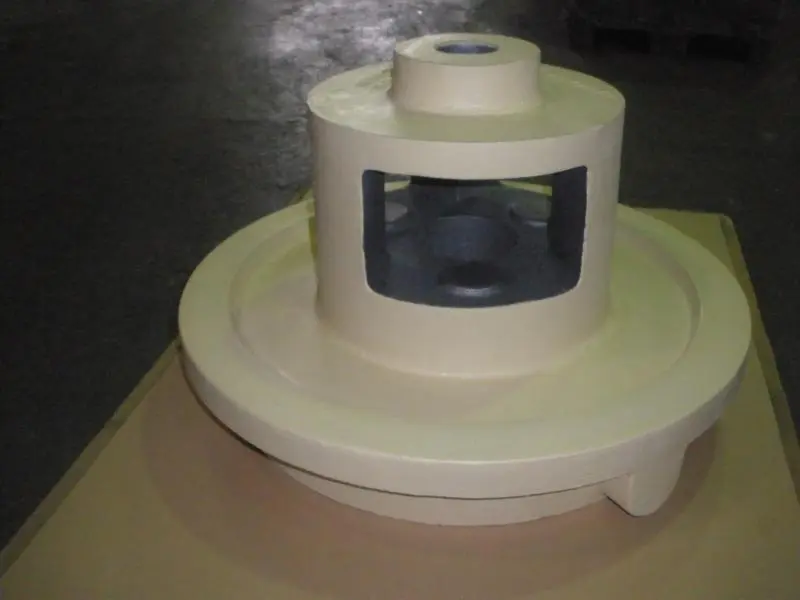

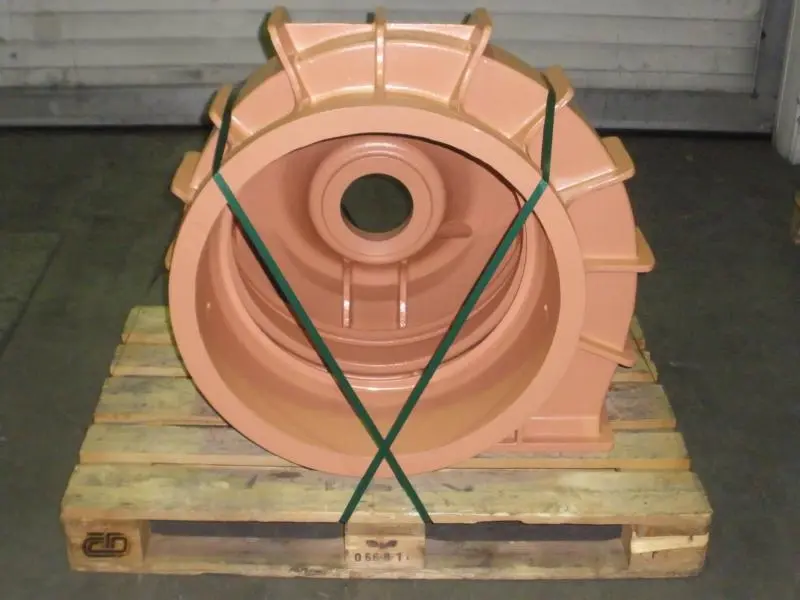

Controlled surface finishing

The surface finishing process is carried out entirely in-house – from professional priming to final coating. Our paint shop with integrated loading station ensures short routes and controlled process flows. After sandblasting and quality inspection – optionally after heat treatment or machining – the parts are re-blasted to guarantee optimal adhesion. A multi-stage coating process follows, including primer, intermediate, and top coat.

Quality monitoring and special coatings

All relevant process parameters can be documented in a paint protocol on request – including painting date, chamber temperature, component temperature, mixing ratio, and drying time. Additional quality assurance options include adhesive tape tests or cross-cut tests. Special coatings include heat-resistant paints, corrosion protection for long-term storage, and coatings in any desired RAL color or custom specifications.

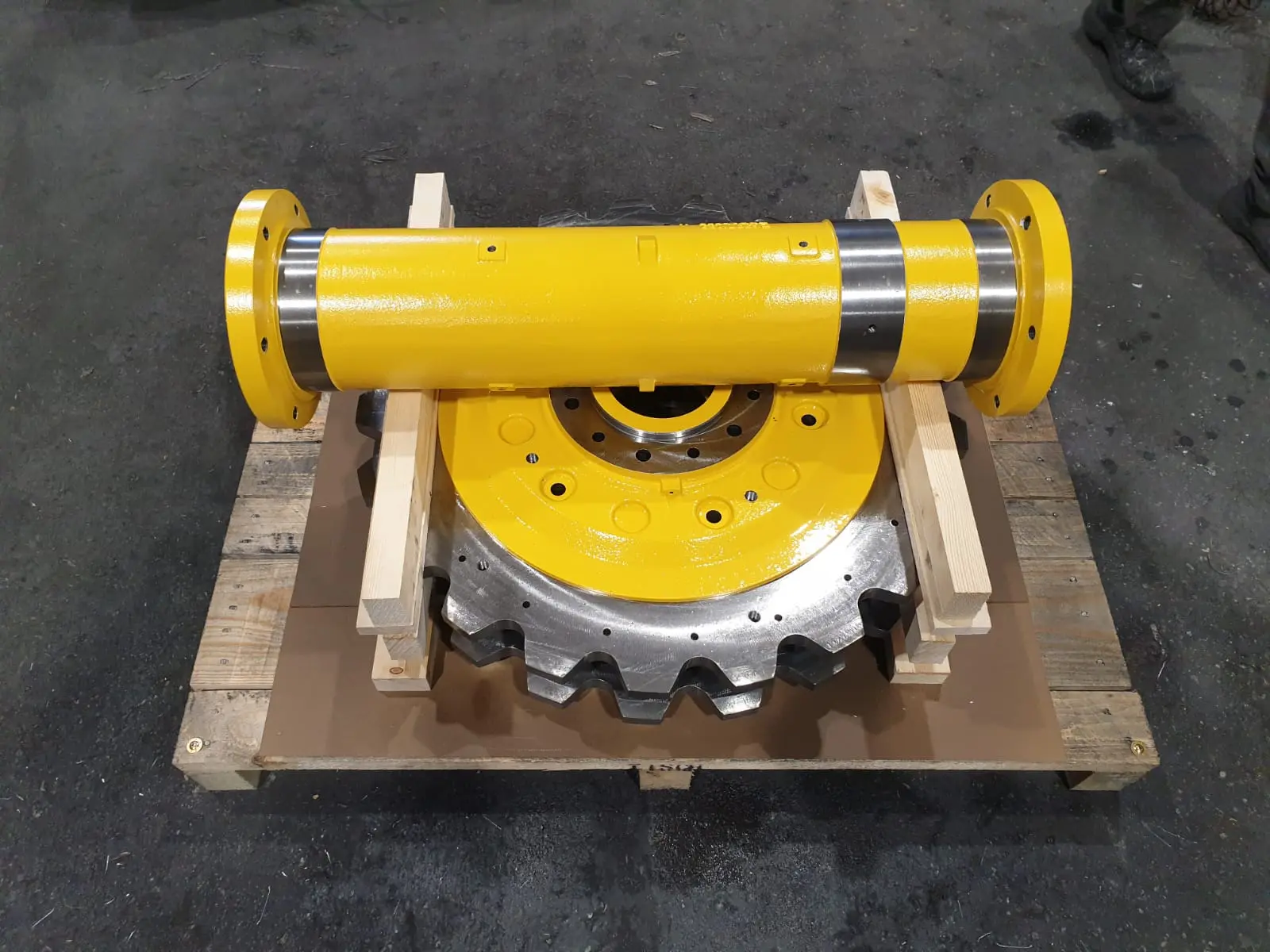

Additional Services for Perfect Castings – Everything from a Single Source

In addition to the casting process itself, we offer a comprehensive range of supplementary services to refine, machine, and prepare your components for their final application. From clean blasted surfaces and precise heat treatments to high-quality coatings, mechanical machining, and induction hardening – every step is carried out with state-of-the-art technology, many years of experience, and the highest quality standards. The result: dimensionally accurate, robust, and visually flawless components that precisely meet your requirements.