Developing optimal solutions together

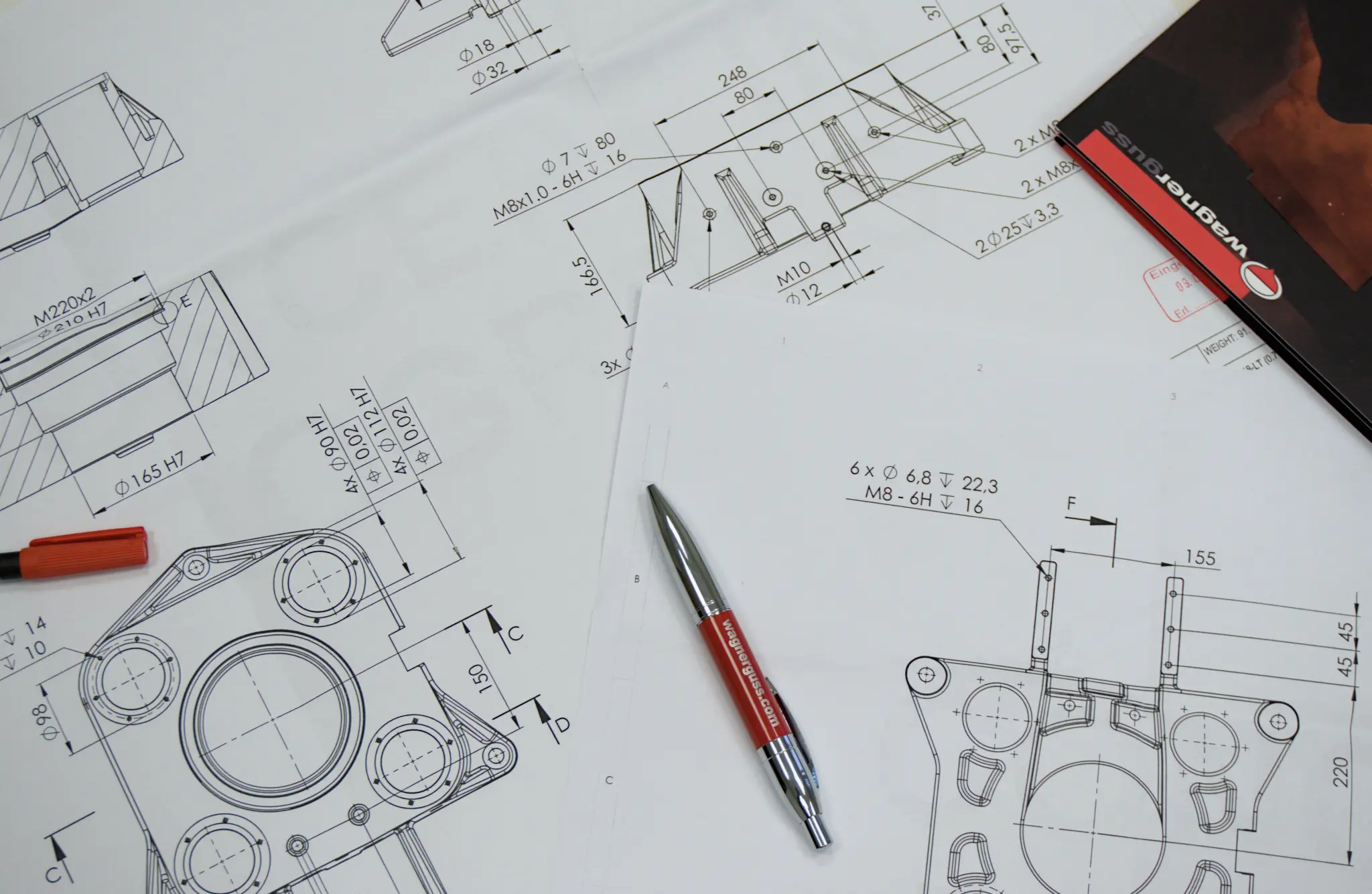

Together with our customers, we develop economically and technically optimal solutions. Already during the design phase, we support the casting-friendly design of components, analyze alternatives between welding and casting, and evaluate their costs, manufacturing effort, and service life.

Experience, efficiency, and precision

Our many years of experience enable well-founded recommendations for material selection, optimized wall thickness distribution, and component geometry to reduce both weight and machining effort. We provide advice on determining quantities and batch sizes, review the most economical production strategy, and accompany the entire process up to the series-ready casting. Close coordination between design, model making, and foundry ensures tailor-made solutions – from small batches to recurring series production. Our lead times depend on batch size and required machining steps – typically a few weeks for single parts and correspondingly longer for complex series production. Examples can be found in our Product Examples / References category, where selected cast parts are presented with their respective manufacturing and processing steps.

From design to model

After completing the design and material coordination, the next step takes place in-house: precise model making. Models can either be manufactured by us or supplied by the customer – both variants are inspected, adapted, and prepared for the casting process. [Link to Model Making] and [Link to Moulding Shop]