Sandblastingas a Contract Service

Clean surfaces for optimal further processing

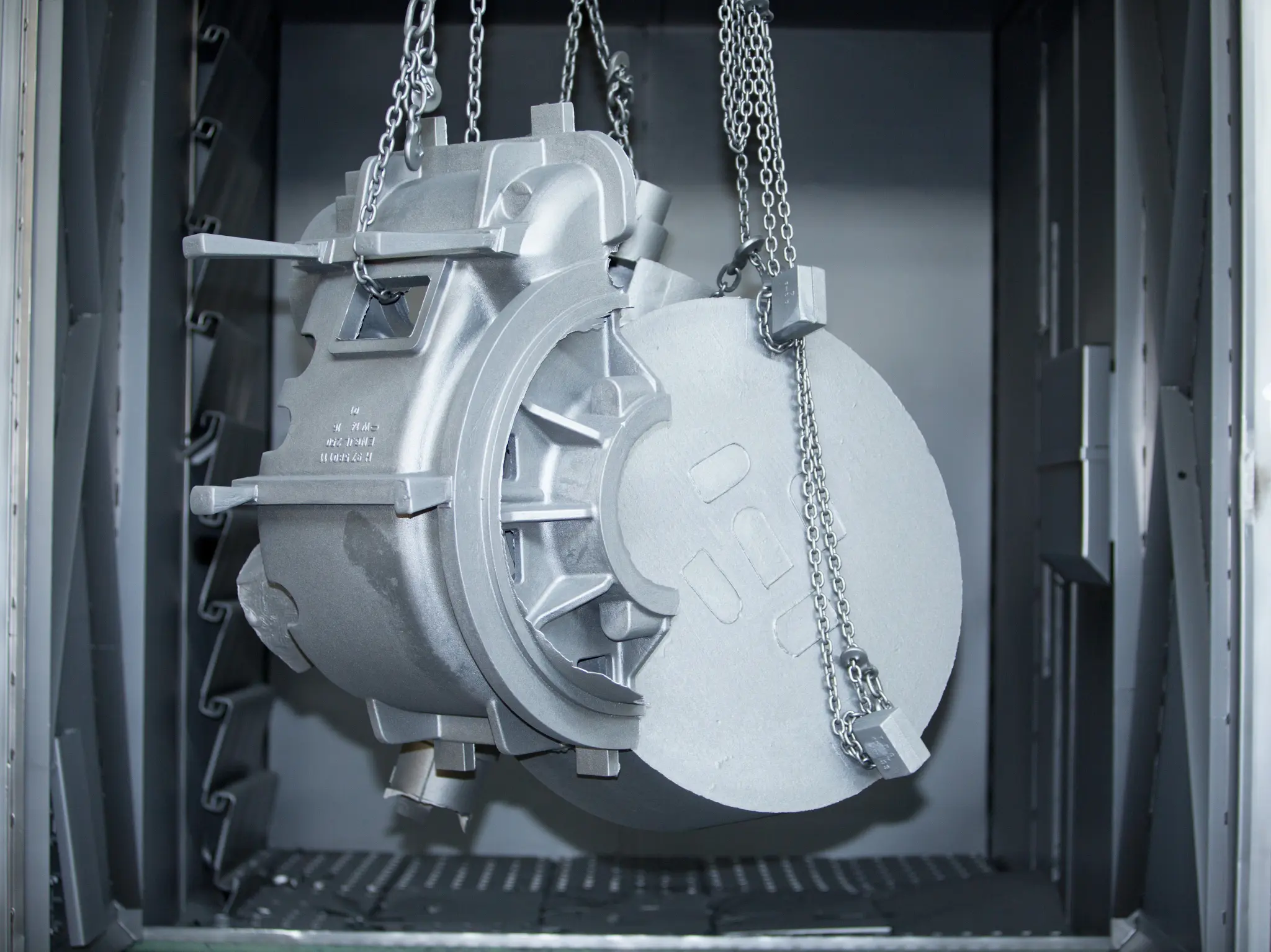

During sandblasting, workpieces are treated with abrasive blasting media to reliably remove contaminants, scale, rust, or casting residue. The uniform surface treatment creates clean, rough adhesion surfaces that are ideal for subsequent processes such as painting, coating, or heat treatment. Depending on the material and requirements, different blasting media and pressure settings are used to achieve the desired surface finish with precision.

Free Blasting System

Our free blasting system enables the flexible processing of a wide variety of components.

Large Component Capacity

We process workpieces up to a size of 3000×3000×2000 mm.

Blasting Media

The blasting media are selected individually based on the material and the desired surface finish.

Sandblasting as a Contract Service

With our modern overhead rail and free blasting systems, we perform blasting work as a contract service. Large cast parts up to 3000×3000×2000 mm can be efficiently cleaned and prepared for subsequent coating. In addition to large cast components, we also process smaller workpieces in our manual blasting unit—customers regularly use this service for blasting parts such as rims, railings, or fence panels.

We clean and strip, among others:

Railings

sandblasting.section2.placeholder

Fence panels/gates

sandblasting.section2.placeholder

Machine components and cast parts

sandblasting.section2.placeholder

Vehicle parts (axle components, frames, brackets)

sandblasting.section2.placeholder

Welded assemblies

sandblasting.section2.placeholder

Construction components

sandblasting.section2.placeholder