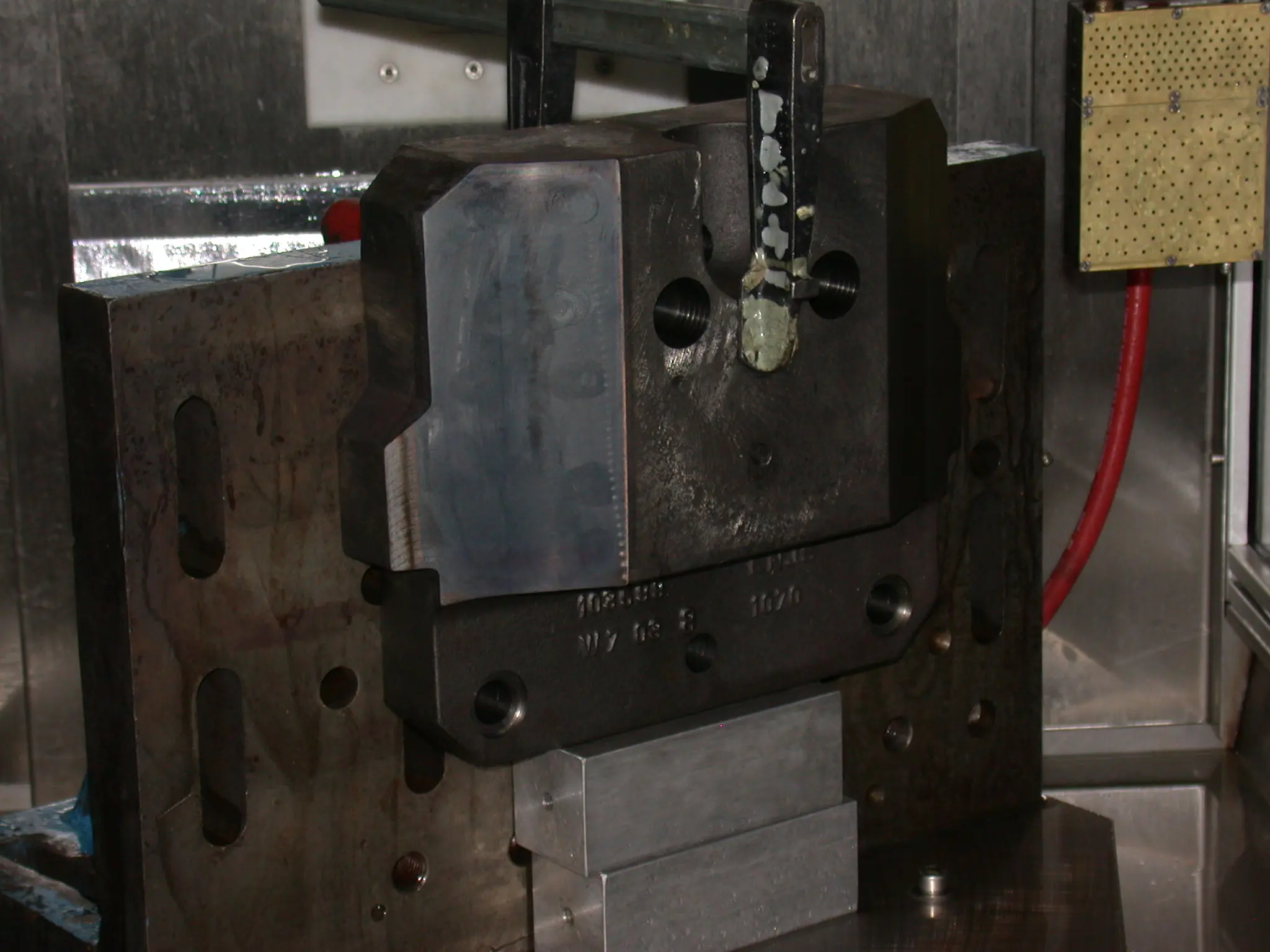

High-tech induction process

Our induction hardening system ranks among the most modern in Europe, enabling the hardening and tempering of workpieces up to 2000 × 600 × 600 mm (hardening length up to 1500 mm) and weights up to 600 kg. Targeted heating and controlled cooling produce wear-resistant and durable surface layers while maintaining a tough, dimensionally stable core.

Applications and advantages

Typical components include clamping elements, plates, tools, wheels, gears, and shafts. The process guarantees precisely adjustable hardness zones, short process times, and reproducible results – ideal for high-stress parts in mechanical and plant engineering.

Additional Services for Perfect Castings – Everything from a Single Source

In addition to the casting process itself, we offer a comprehensive range of supplementary services to refine, machine, and prepare your components for their final application. From clean blasted surfaces and precise heat treatments to high-quality coatings, mechanical machining, and induction hardening – every step is carried out with state-of-the-art technology, many years of experience, and the highest quality standards. The result: dimensionally accurate, robust, and visually flawless components that precisely meet your requirements.