Quality Assurance at the Highest Level

After production and finishing, quality assurance follows — a central component of our entire manufacturing process. Our company is TÜV-certified according to ISO 9001:2015 and approved by the international classification societies ABS, BV, CCS, DNV-GL, KR, NKK, LR, and RINA. Upon request, we conduct on-site audits together with our customers to ensure full transparency and traceability.

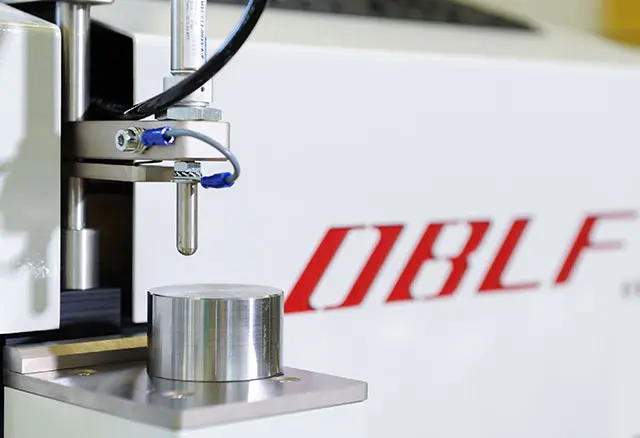

Modern Testing and Measuring Technology

To ensure our high quality standards, we rely on a wide range of precise testing and measuring technologies. From modern analytical methods to destructive and non-destructive testing, as well as metallographic examinations, we guarantee seamless control of all production steps. This ensures that every component meets our technical requirements and the expectations of our customers.

ISO 9001 certified since 2009

We regard quality as a commitment to our customers. On-site audits, continuous inspections, and the use of state-of-the-art analysis and measurement technology ensure that every casting meets the highest technical and safety standards. For quality assurance, we use comprehensive testing and measuring technology. this ensures that every cast part precisely meets the defined specifications, standards, and customer requirements. Upon request, we provide detailed inspection reports documenting all relevant measurement and analysis results, thus offering complete and transparent proof of quality.