What We Stand For

At Wagnerguss GmbH, maximum precision, quality, and reliability are at the core of everything we do. As a medium-sized manufacturer, we combine traditional craftsmanship with state-of-the-art production technologies to create tailor-made castings for demanding applications.

Cutting-edge manufacturing technologies ensure consistent dimensional accuracy and repeatability. With an annual capacity of around 6,000 tons, we serve the European market comprehensively while remaining flexible for customer-specific requirements. Our customers include companies from the paper, printing machinery, machine tool, and plastics machinery industries, as well as turbine and pump manufacturing, gear production, and gear technology.

Our Services

From the first idea to the assembly-ready casting, we offer our customers all services from a single source. Our comprehensive expertise includes consulting, model making, core making, casting production, post-processing, quality assurance, and logistics. We combine long-standing experience with state-of-the-art technology to provide economical, precise, and reliable solutions at every stage of the project.

Consulting

Together with our customers, we develop optimal solutions. Our experience flows into the design phase to optimize manufacturing processes, select suitable materials, and implement technical requirements with precision.

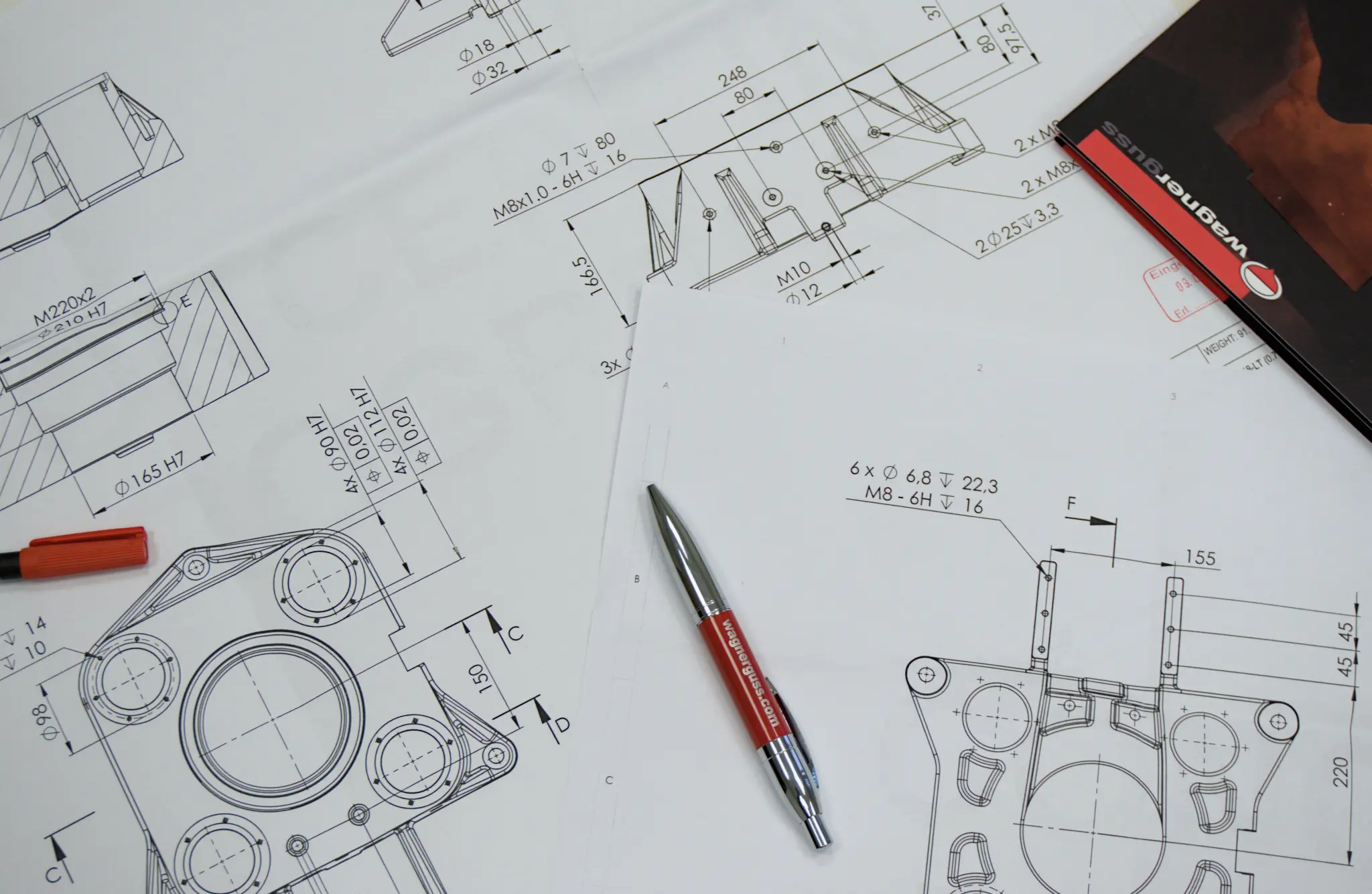

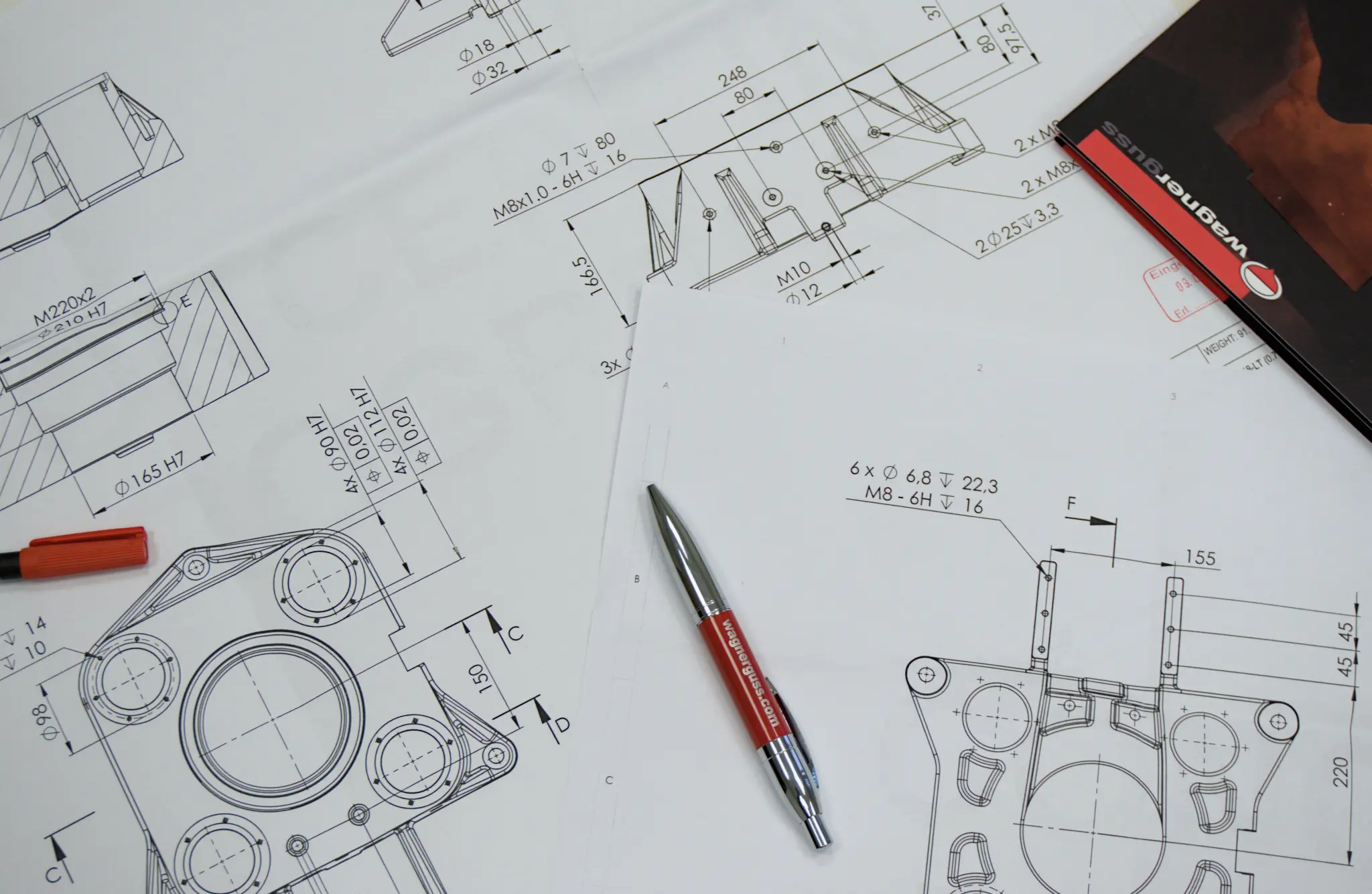

Model Making

Every casting begins with the model – crafted from wood, polystyrene, plastic, or metal with the highest level of craftsmanship. Our in-house joinery enables precise and rapid production of custom models. Dimensional accuracy and quality begin here. Our high-bay storage system with over 20,000 stored models ensures quick access and efficient production workflows.

Casting

In our hand-molding foundry, we produce high-quality castings from EN-GJL and EN-GJS materials as well as special alloys according to customer specifications. Precise molding, careful finishing, and modern blasting systems ensure flawless surfaces and dimensional accuracy at every production stage.

Heat Treatment

Depending on the workpiece requirements, we perform stress relieving, tempering, ferritizing, or pearlitizing in our in-house annealing chambers. This allows us to achieve the desired mechanical properties and reliably eliminate material stresses.

Coating

Surface finishing is performed entirely in-house – from proper priming to final coating. In our modern painting facility, castings receive a flawless appearance and long-lasting surface protection.

Machining

With modern CNC-controlled milling, turning, and drilling machines, we machine castings with the highest precision. The result: assembly-ready components whose dimensional accuracy and surface quality meet the highest standards.

Contract Hardening

Our induction hardening system is one of the most advanced in Europe. We harden and anneal workpieces up to 600 kg, creating wear-resistant surfaces and optimal strength properties.

Logistics

Finished products are stored in our dispatch warehouse and shipped on schedule by freight forwarding partners. We comply with customer-specific shipping requirements, use special pallets when needed, and secure castings professionally for transport. Protective packaging ensures safe delivery and shields components from environmental influences.